It is not just about organic acids

Written by Sammy Vanden Driessche, Raw Material Specialist

Nutritionists know that digestion starts in the stomach, but do they formulate accordingly? In the past, diets for young piglets, that are known to have an immature digestive system that produces only low levels of endogenous gastric acid (HCl) until 6-8 weeks of age, were traditionally supplemented with an (often arbitrary) amount of organic acids. The use of organic acids was common practice to anticipate gut health challenges like post-weaning diarrhea due to maldigestion and the proliferation of pathogenic bacteria. However, arbitrary inclusion of organic acids in diets may lead to undesired effects, such as reduced feed intake and unnecessary increases in feed cost.

The arbitrary use of high amounts of organic acids originates from times when piglets were fed high protein diets supplemented with high pharmacological amounts of zinc oxide (ZnO) to prevent post-weaning diarrhea. These diets were known to have a strong buffering effect in the stomach, and piglet nutritionists anticipated this effect by adding high amounts of organic acids to the diet. Over the years, protein levels in piglet diets have decreased and the pharmacological use of ZnO has been banned in several parts of the world. Even though the buffering capacity of diets has consequently decreased accordingly, piglet nutritionists often continue to use organic acids as acidifiers. In-depth knowledge of, and awareness about, the Acid Binding Capacity (ABC) of raw materials enable a well-reasoned use of organic acids and a more cost-effective feed formulation, as applied by Agrifirm nutritionists in daily practice.

ABC: the start… of smart formulation

Acid Binding Capacity (ABC) is a well-known characteristic of raw materials or complete feed. The higher this value, the higher the capacity to neutralize acids – which is of particular importance when formulating diets for young piglets. A higher ABC value of the feed not only means that a higher quantity of gastric HCl is required to keep the stomach’s pH sufficiently low. It also means that, after feed intake, it will take longer for the stomach’s pH to return to a value sufficiently low to inhibit pathogens. This “increased pH” time interval occurring after feed intake should be kept as short as possible to minimize the risk of pathogenic bacteria surviving and migrating into the duodenum.

The ABC is an analytical parameter that is determined in vitro by adding acid (or base) to a raw material or feed to achieve a preset pH. This preset pH correlates with the optimal pH for the animal’s digestive enzymes. It is generally accepted that pH 4.0 is a good reference value for young piglets, because this pH is the maximum value for the proteolytic activity of pepsin, and it is sufficiently low to allow for good (protein) digestion and pH-based pathogen suppression. Therefore, most nutritionists consider ABC-4 (i.e. the amount of acid or base that must be added to an ingredient or feed to reach pH 4.0) to be the setpoint practically relevant for piglets. ABC-4 values can be found in literature and are expressed in milli-equivalents of acid per kg (meq H+/kg). Materials consuming acid have positive ABC-4 values, those adding acid(ity) have negative values.

Aim low

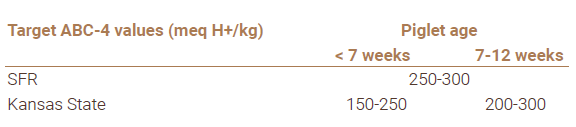

Limited gastric acid production is typical for young piglets, so ABC-4 values are most relevant in young animal nutrition. It is generally acknowledged that the gastric acid production by a piglet may remain insufficient (pH>3.5-4.0 in fasting state) until 6-7 weeks of age, and suboptimal (pH>2.5-3.0 in fasting state) until approximately 60 days (8-9 weeks). Research by F. Molist et al. of Schothorst Feed Research (SFR, NL) and Stas et al. of Kansas State University establishes target ABC-4 values of a complete feed as a function of the animal’s age (Table 1).

When formulating piglet diets, nutritionists can assume that ABC-4 values of raw materials are additive – i.e., that the ABC-4 value of a complete feed can be predicted with sufficient accuracy by the weighed sum of the ABC-4 values of the individual raw materials present in the feed. Therefore, a good knowledge of the ABC-4 values of the different classes of raw materials allows nutritionists to steer the dietary ABC-4 value of a diet towards the target value.

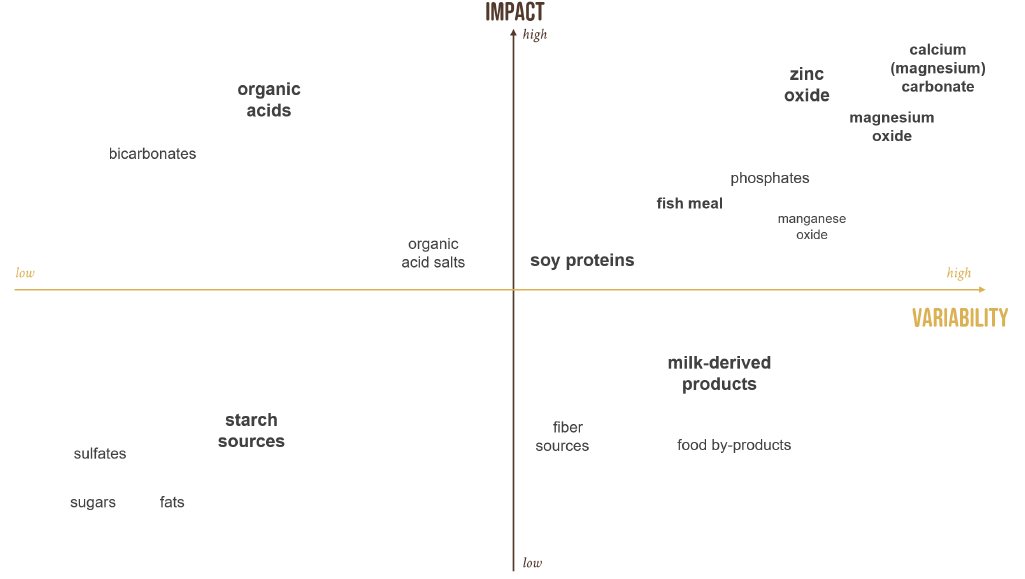

Natural = variable

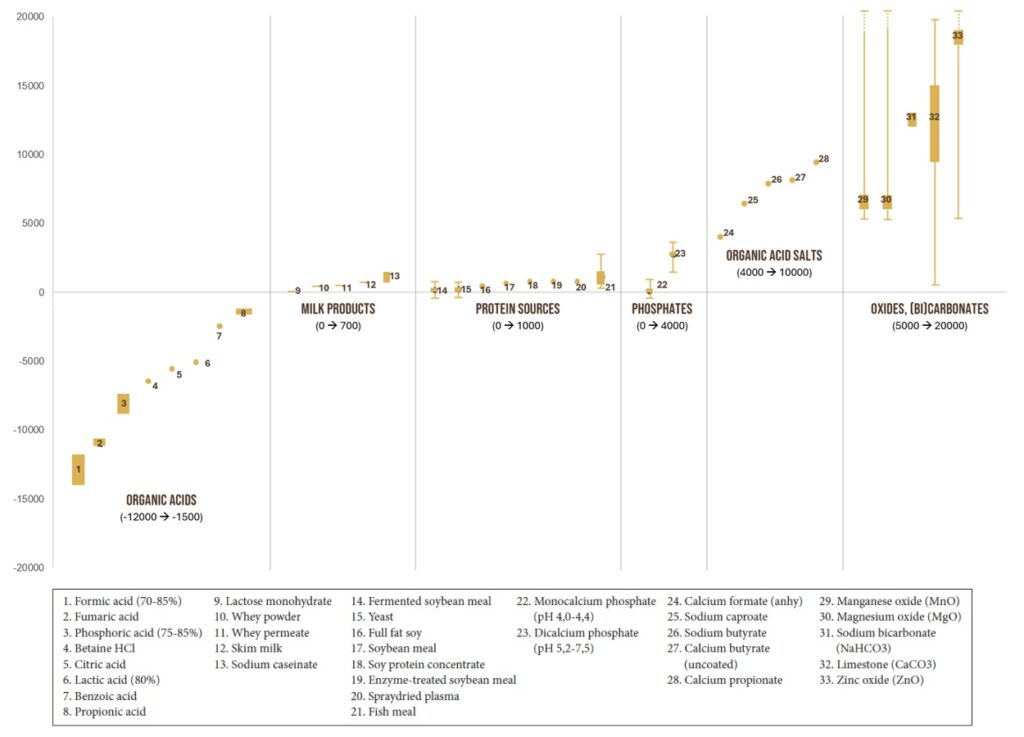

Pure raw materials containing one type of molecule (e.g., salt NaCl, sodium bicarbonate NaHCO3, fumaric acid, calcium propionate) have a constant chemical composition and predictable ABC-4 values with low batch-to-batch variability. For these raw materials, differences in ABC-4 values result mainly from their level of concentration – i.e., from the presence of other compounds that dilute the ingredient without having a significant buffering capacity themselves (e.g., water, fat coatings, inert silica carriers). In general, for these types of raw materials, the ABC-4 values found in literature can be relied upon for formulation. Natural or nature-derived raw materials (e.g., starch, protein, fat and fiber sources, and minimally processed minerals) have a more variable composition and, consequently, more variable ABC-4 values between nutritionally equivalent batches. For these types of ingredients, depending on their inclusion level and their potential impact on the ABC-4 value of the feed, it is recommended to analytically determine the ABC-4 value of the batch itself and not rely on literature values (Figure 1).

Macros: high inclusion, limited impact

High inclusion levels make macro-ingredients nutritionally important, but from an ABC-4 perspective, some are less relevant because major nutrient classes like carbohydrates (starch, sugar) and fats have almost no buffering capacity. Proteins, minerals and fiber, however, do have an impact.

Cereals like barley, wheat, corn and rye have low, positive ABC-4 values (60 to 120 meq/kg) and have a small, increasing effect on the ABC-4 of the diet, even at high inclusion levels. Limited variability in ABC-4 values stems from different protein and fiber contents.

Depending on their structural and compositional characteristics, fiber-rich ingredients have variable acid-binding properties, and low-to-moderate, positive ABC-4 values (70 to 400 meq/kg). They may also have high water-binding capacity, leading to a higher gastrointestinal viscosity and complicating the acid diffusion in the stomach. Although fibers have been studied primarily for their potential to improve gut health, their impact on ABC-4 and acid diffusion rate is a point of consideration when integrating them into diets.

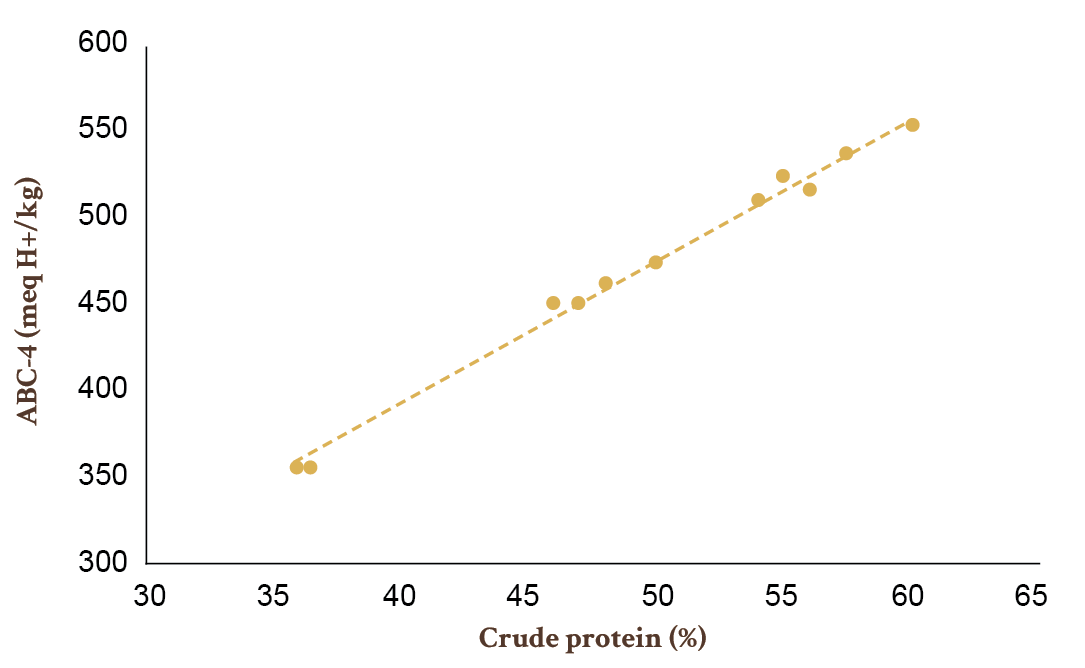

Protein sources are the macro-ingredients that potentially have the largest impact on the ABC-4 value of a feed. Their higher ABC-4 values (0 to 1000, most commonly 400 to 600 meq/kg) compared to starch and fiber sources, are explained by the higher buffering capacity of peptides due to the presence of free amine groups (lysine, arginine and histidine) and free carboxylic groups (glutamic and aspartic acid). Raw materials containing the same protein type (e.g., soy protein) have higher ABC-4 values as the protein content increases (Figure 2). Different protein types (soy, potato, wheat gluten, …) with the same crude protein content have different ABC-4 values due to their different amino acid and structural composition.

Research (Stas et al. 2024) indicates that some protein sources exhibit a wide range of ABC-4 values, with different batches of the ‘same’ raw material having significantly different buffering capacities (e.g., fish meal). For these, it is advisable to make an ABC-4 determination on the individual batches and not rely on literature values, especially if their inclusion levels in the feed are high. Other sources (e.g., blood plasma powder) have relatively similar batch-to-batch protein levels and uniform ABC-4 values.

Milk-derived ingredients vary in ABC-4 (0 to 700 meq/kg), due to differences in protein and mineral content and in the type of processing. Pure lactose has no acid buffering capacity. Milk powders and sweet whey powders have quite uniform ABC-4 values, due to their relatively constant protein level. In whey permeates, crude ash and especially phosphorus content, correlate positively with ABC-4 values.

Fats have almost no acid buffering capacity when present in their natural (triglyceride) form and are of little relevance with respect to the ABC-4 calculation of a feed. Free fatty acids, either added on purpose or generated by fat source deterioration, are minor contributors of acidity (small negative ABC-4 value).

The devil is in the minors

Due to their high absolute buffering capacities, some of the minor feed ingredients may have a large impact on the ABC-4 of a diet (Figure 4). Oxides, (bi)carbonates and phosphates are the most relevant minerals (5000 to 20000 meq/kg) for ABC-4. Zinc oxide (ZnO) deserves particular attention because of its very high capacity to neutralize acids and its potential to form poorly soluble zinc salts upon reaction with organic and phosphoric acids. As can be seen from Figure 1, the ABC-4 value of ZnO can be highly variable, depending on manufacturing conditions, levels and types of impurities (Figure 3) and particle size. Because ZnO has a significant impact on the ABC-4 of a feed (even at low inclusion levels), it is definitely one of the raw materials for which an ABC-4 determination of individual batches/origins is recommended. The same applies to other low soluble oxides and carbonates (e.g., MgO, MnO, CaCO3). Their acid buffering capacity is theoretically very high, but can vary significantly depending on origin, purity and particle size, which justifies individual batch analysis.

Calcium and magnesium phosphate salts (0 to 4000 meq/kg), obtained by the treatment of the aforementioned carbonates and oxides with phosphoric acid, have different ABC-4 values as a function of the relative amount of phosphoric acid used for neutralization. Monocalcium phosphate (MCP) and dicalcium phosphate (DCP) are nutritionally similar, but the former has a low pH and negligible or slightly negative ABC-4, whereas the latter buffers acid(ity) and has high positive ABC-4. Analogously, not all magnesium phosphates have the same buffering effect. If available, use phosphate salts with low ABC-4 values, as they also offer the best phosphorus availability.

When selecting organic acids during feed formulation, several factors (impact on feed palatability, anti-microbial effect, gut health improvement) must be taken into account. In the context of ABC-4, their acidification power to lower buffering capacity and improve the digestibility of the feed is most relevant and differs greatly (-12000 to -1500 meq/kg) between acids as a function of concentration (e.g., 100% fumaric versus 50% lactic acid), acid strength (pKa value), and molecular weight.

In buffered organic acids and salts of organic acids (e.g., calcium propionate), part or all of the acidification power has been removed. These types of raw materials may be equivalent to the organic acids themselves in terms of organic anion sources (e.g., lactic acid and calcium lactate are both sources of lactate) but from an ABC-4 perspective, they are completely opposite. Fully neutralized salts of organic acids do not acidify at all. On the contrary, they actually increase the pH as can be seen from their positive ABC-4 value (4000 to 10000 meq/kg).

Role of processing

Processing of feed ingredients may alter their ABC-4 value, depending on the type of treatment. In general, enzymatic treatment alone has limited impact, unless it requires significant pH correction to maximize the enzyme’s hydrolytic activity. The impact of fermentation (e.g., of soy protein sources) depends on the type(s) of micro-organisms used (lactic acid bacteria, Bacillus species, fungi). Both the required initial setpoint pH and the metabolites produced (organic acids) determine the final buffering capacity of the ingredient. Fermentation usually results in lower ABC-4 values.

The presence of acids, either added on purpose (e.g., phosphoric acid during production of DCP or MCP) or naturally present (e.g., lactic acid in acid whey powder), will result in lower ABC-4 values. On the other hand, the use of alkaline substances (e.g., lye) during processing may lead to neutral or mildly alkaline ingredients with a higher ABC-4 value (e.g., caseinates).

First contemplate, then formulate

Organic acids fulfill multiple roles in weaning diets for piglets. As acidifiers, they must be used in conjunction with a good knowledge of the intrinsic properties (ABC-4) of the other feed ingredients. Some of these have a limited effect on the buffering capacity of the final diet and have very similar batch-to-batch ABC-4 values; whereas others may have a significant impact even at low inclusion. The latter warrant regular individual batch testing, especially if they show highly variable ABC-4 depending on origin. Agrifirm’s expertise in testing and selecting dedicated ingredients for young animal nutrition ensures the formulation of high-performance, cost-effective feeds.

References available upon request

This contact was suggested based on the location you are browsing from. You can of course also consult our other contacts and locations here.